PSMV

Medium Voltage Drive

3.3-11kV

250-6000KW

The medium-voltage drives manufactured by this company use Cascaded H-Bridge Multilevel Inverter technology. These drives are composed of multiple low-voltage power cells connected in series.

These drives are built using low-voltage IGBTs, achieving an efficiency of over 98%. The power factor of these drives exceeds 96% without the need for a power factor correction capacitor.

These drives, compliant with IEEE519_1992 requirements, generate harmonics of less than 5%, and the input current waveform is nearly sinusoidal. Due to the multilevel nature of the output voltage waveform, the motor output current is sinusoidal, allowing installation on standard motors and cables used in the system.

Other features of these drives include modularity, meaning all power cells are identical and easily replaceable. Additionally, all power cells are isolated from the control section via optical cables, and their control and command signals are transmitted in a modulated form through two optical fiber lines.

- 33 years of manufacturing experience.

- An annual production capacity of 40,000 units.

- The largest drive manufacturer in the Middle East.

- Certified as a Knowledge-Based Company by the Vice-Presidency for Science and Technology.

- CE Certificate of the European Community.

| Performance | Specifications |

|

| System Protections | Overload Capacity | 120% of rated current: 2 minutes

150% of rated current: instantaneous trip |

| Transformer Protections | Transformer overcurrent, alarm and trip for each of the three transformer windings, and surge voltage protection. | |

| Independent Power Cell Protections | Overheating of power cell heat sinks, undervoltage protection, overvoltage protection (above 1170 V), input phase loss protection, short-circuit protection with fast-blow fuses, optical cable disconnection protection, and bypass protection (optional). | |

| Inverter Protections | Overcurrent, inverter overvoltage, overheating of power cell cabinet, control power phase loss protection, short-circuit protection of control power supply, cabinet door lock, overcurrent, short-circuit, and overtemperature protection of cooling fan motors, ground fault protection (optional), HMI signal disconnection, serial communication network fault, central control board fault, and speed signal or feedback loss. | |

| Automatic Control Protections | Overcurrent control protection during acceleration, which prevents excessive speed increase and manages motor ramp-up time, and overvoltage control protection during rapid deceleration, which prevents excessive speed drop—these two protections are referred to as Stall Prevention. | |

| Motor Thermal Protection | Capability to monitor the temperature of motor windings and bearings using 4 to 8 Pt100 modules (optional). | |

| Hardware Control Functions |

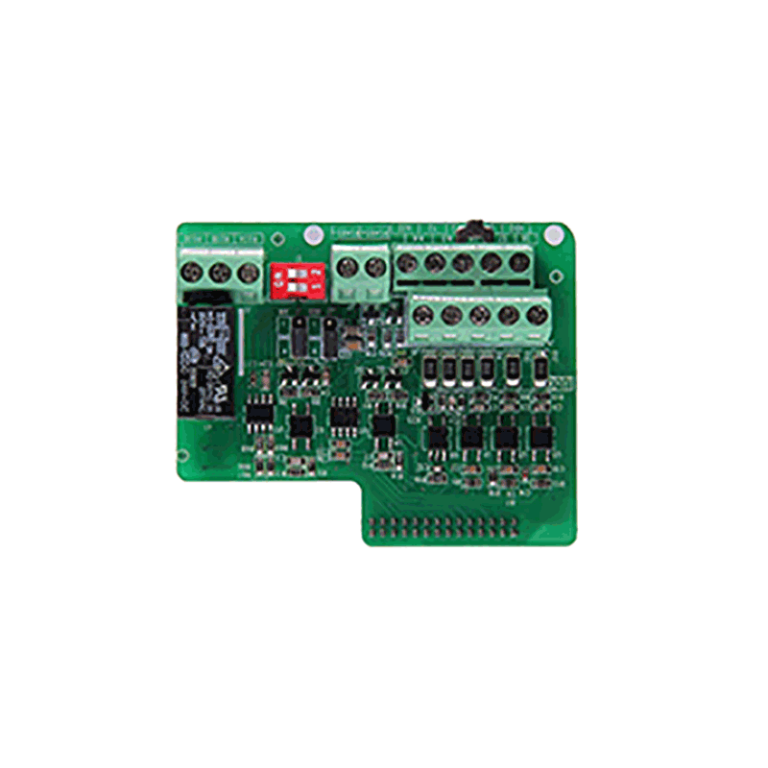

Analog Input | Four channels (AI1–AI4) 2–10 V / 4–20 mA |

| Analog Output | Two channels (AO1, AO2) 2–10 V / 4–20 mA | |

| Acceleration and Deceleration | 5~1600sec | |

| Digital Inputs and Outputs | 22 relay outputs and 14 relay inputs | |

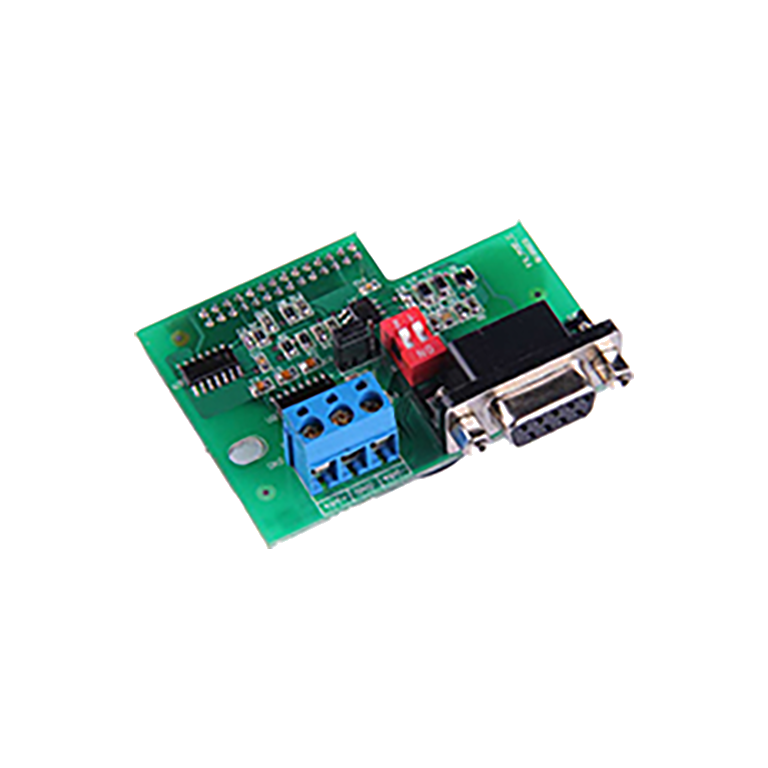

| Network Communication | Isolated RS485 interface, Modbus RTU, Profibus DP (optional), Industrial Ethernet protocol (optional). | |

| 10-inch Panel Interface | Touch Screen DELTA DOP-110IS | |

| Medium Voltage Main Switch Control | The drive’s readiness conditions for closing the upstream disconnector or for its forced opening are controlled via the output relay. | |

| Bypass Switch | Capability to bypass the power cell (optional). | |

| Software Control Functions | Panel Display | • Capability to display and adjust system parameters and functions

• Error log recording up to 256 MB or more using an SD card • Display of system alarms and faults as Heavy or Light Faults • Ability to identify the type of fault and the location of each defective power cell independently • Display of control status and trends with a resolution of 1024 × 600 pixels • Parameter storage with Upload and Download capability, and access control via password |

| Function for Identifying Motor Parameters | This function is used to identify motor parameters when operating in vector control mode. It should be noted that the motor specifications must be provided to the drive prior to executing this function. The identification process is then completed in two stages: static and dynamic. | |

| Local/Remote Control | Access to commands via the panel, near the motor, or through the DCS system can be managed through software. | |

| Flying or Rotating Speed Start Capability (Ability to Resume Control of a Spinning Motor) | When the motor is started (Run command), the system first detects the current rotating speed of the motor. It then continues acceleration or deceleration from that detected speed to reach the desired operating speed. | |

| Automatic Start | Capability of Automatic Drive Restart in Case of Unintentional Power Supply Interruption | |

| Jump Frequency | Capability to Set Two Separate Frequencies to Prevent the Motor from Operating at Resonance or Experiencing Severe Vibration | |

| Fan Control | Setting the Fan Turn-Off Delay Time After Motor Stop | |

| Voltage Optimization Control | AVR System for Motor Voltage Regulation | |

| Feedback Integrator | This integrator is used to determine speed by stabilizing process parameters such as pressure, flow rate, and others. | |

| Performance | Specifications |

|

| Device Input | MV Transformer (Medium Voltage Transformer) | Air-cooled dry-type transformer with 18 to 54 pulse output, depending on the network voltage level, and an auxiliary winding to supply three-phase control voltage plus neutral. |

| Input Voltage | Three-Phase 3.3 kV ~ 11 kV (−15% ~ +5%) | |

| Input Current | According to the device rating | |

| Input Frequency | Permissible Frequency: 50 Hz or 60 Hz (±10%) | |

| Power Factor Correction | 0.96 < | |

| Efficiency | Inverter Section Efficiency: >98% (Overall Transformer and Inverter Efficiency: >95%) | |

| Input Harmonics | Compliance with IEEE 519 Standard | |

| Voltage Sag Ride-Through Threshold | Five Cycles | |

| Control Power Supply | 380VAC (3Ph+N) | |

| Live Supply | For PLC and Control Section: 110–240 V AC/DC | |

| Device Output |

Waveform Generation Technique | Low-Voltage Power Cells with Cascaded H-Bridge Multilevel Configuration |

| Modulation Technique | SVPWM, SPWM (for Scalar and Vector Control) | |

| Output Voltage | 0 to Rated Input Voltage | |

| Output Frequency | 0~80Hz | |

| Frequency Resolution | 0.01Hz | |

| PLC Control Section | Siemens S7-200 Smart | |

| Central Microcontroller | 32-bit Texas DSP and FPGA | |

| Installation Environment |

Operating Ambient Temperature | 0 ~ 40 ºC (up to 45 ºC with derating) |

| Transport Ambient Temperature | -10 ~ 70 ºC, Non-Condensing | |

| Storage Ambient Temperature | -10 ~ 60 ºC, Non-Condensing | |

| Humidity | Non-Condensing, Up to 90% Maximum Humidity | |

| Installation and Maintenance Conditions | Enclosed Space with Controlled Ambient Temperature (Indoor) | |

| Installation Altitude | Below 1500 m; above this, power is reduced by 1% for every 100 m up to 3000 m. | |

| Drive Cooling | Forced Air Cooling with Fan | |

| Dust | Free of conductive and corrosive dust, <6.5 mg/dm³ | |

| Product Color | RAL7032 | |

| Enclosure Protection (IP) | IP30 | |